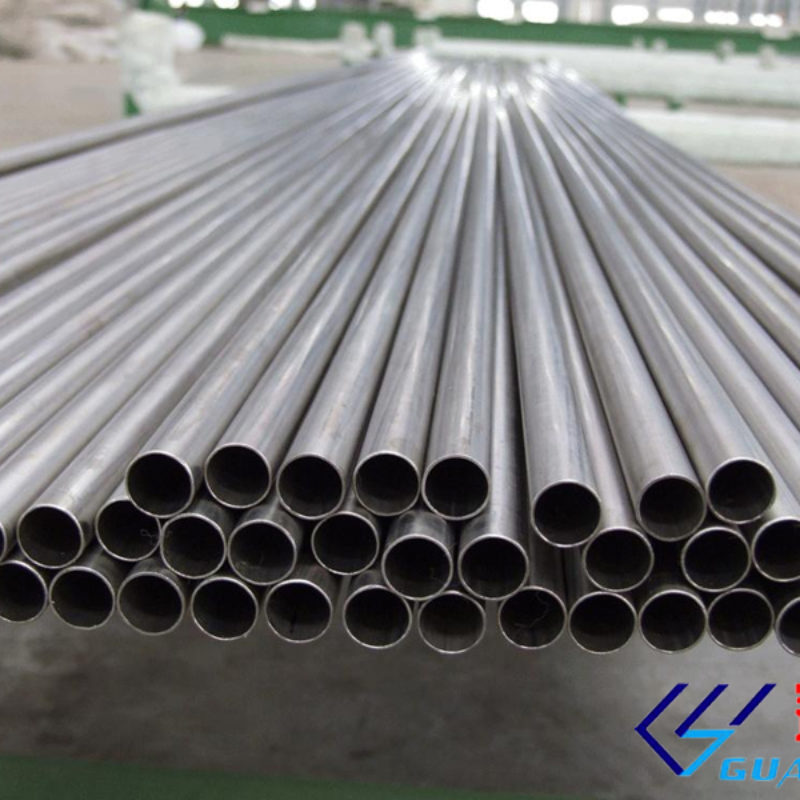

Incoloy 825 Pipe, Alloy 825 Tubing ASTM B163 B423 ASME SB163 SB423 N08825 Nickel Alloy Seamless Tubes Tubing Pipes

Request for QuotationASTM B163 B423 ASME SB163 SB423 N08825 Nickel Alloy Seamless Tubes Tubing Pipes Characteristic as below:

1. Good stress corrosion cracking resistance in chloride and sour (H2S/Cl-) environments

2. Superior resistance for pitting and crevice corrosion performance better than 316L Stainless Steel

3. Good anti-oxidation and non-oxidzing heat acid performance

4. Good mechanical performance in both room temperature and up to 550℃

5. Have the pressure vessel authenticate when manufacture temperature up to 450℃

6. Very good resistance to corrosion in acidic media such as sulfuric acid

7. Good Weldability

Pressure Vessels

UNS N08825 is approved for pressure vessel operating temperatures up to 525°C (AS1210, AS4041), 538°C (ASME Boiler & Pressure Vessel Code, Sections I, III, VIII, IX, Cases 1936, N-188). Brittle phases may form in alloy 825 at temperatures above ~ 540°C, so it is not normally used at these temperatures, where creep-rupture properties would be design factors.

Incoloy 825 Pipe, Alloy 825 Tubing Metallurgical structure: 825 is the face-centered cubic lattice structure.

Incoloy 825 Pipe, Alloy 825 Tubing Corrosion resistance:

825 is an all-purpose project alloy, have good corrosion resistance of the acid and alkali metal property in both oxidation and reduction environments. High nickel content made it with effective stress corrosion cracking resistance performance. 825 have excellent corrosion resistance in different kinds of media, such as sulfuric acid, phosphoric acid, nitric acid and organic acid, alkali metal such as sodium hydroxide, potassium hydroxide, and hydrochloric acid. A variety of media corrosion of nuclear-burning dissolver show 825 high integrated prpperty, like sulfuric acid, nitric acid and potassium hydroxide are all dealing in a same device.

ASM specifications for Incoloy Alloy 825 UNS N08825.

| Specification | Title |

| ASTM B163 | Seamless Nickel and Nickel Alloy Condenser and Heat Exchanger Tube |

| ASTM B423 | Nickel-Iron-Chromium-Molybdenum-Copper Alloy (UNS N08825 and N08221)* Seamless Pipe and Tube |

| ASTM B424 | Ni-Fe-Cr-Mo-Cu Alloy (UNS N08825 and UNS N08221)* Plate, Sheet, and Strip |

| ASTM B425 | Ni-Fe-Cr-Mo-Cu Alloy (UNS N08825) |

| ASTM B704 | Welded UNS N06625 and UNS N08825 Alloy Tubes |

| ASTM B705 | Nickel-Alloy (UNS N06625 and N08825) Welded Pipe |

| ASTM B751 | General Requirements for Nickel and Nickel Alloy Welded Tube |

Incoloy 825 Pipe, Alloy 825 Tubing Chemical composition:

| Alloy | % | Ni | Cr | Fe | C | Mn | Si | Cu | Mo | Al | Ti | S |

| Incoloy 825 N08825 | Min. | 38 | 19.5 | balance | 1.5 | 2.5 | 0.6 | |||||

| Max. | 46 | 23.5 | balance | 0.05 | 1.0 | 0.5 | 3.0 | 3.5 | 0.2 | 1.2 | 0.03 |

Incoloy 825 Pipe, Alloy 825 Tubing Physical properties

| Density / Specific Gravity | 8.1kg/dm³ 0.30 lb/in³ |

| Melting point | 1370-1400℃ |

Incoloy 825 Pipe, Alloy 825 Tubing Alloy minimum mechanical properties in the room temperature

| Alloy state | Tensile strength Rm N/mm² | Yield strength R P0. 2N/mm² | Elongation A 5 % | Brinell hardness HRB Max |

| N08825 Hot Finished | 517 | 172 | 30 | 200 |

| N08825 Cold Finished | 586 | 241 | 30 | 200 |