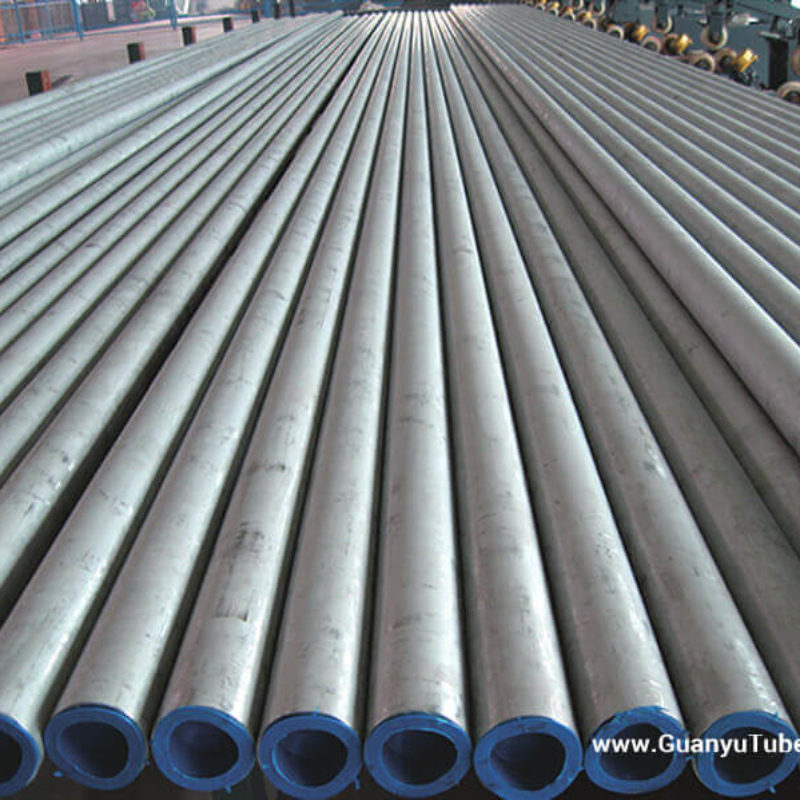

Alloy 20 Pipe UNS N08020 Nickel Alloy Tubing Tubes Pipe

Request for QuotationAlloy 20 Pipe ASTM B729 N08020 DIN 17751 2.4660 is a high-corrosion resistant alloy, which shows very good resistance to phosphoric acid, nitric acid, sulfuric acid in chloric media. DIN 17751 2.4660 Alloy 20 is chiefly used in the chemical industry, apparatus engineering and heat exchanger.

Alloy 20 Pipe is a nickel-iron-chromium austenitic alloy that was developed for maximum resistance to acid attack, specifically sulfuric acid. This superalloy has excellent resistance to general corrosion, pitting, and crevice corrosion in chemicals containing chlorides and sulfuric, phosphoric, and nitric acids. It also contains niobium for stabilization against sensitization and resultant intergranular corrosion.

Alloy 20 Pipe combines excellent corrosion resistance with elevated mechanical properties and relatively easy fabrication. Although originally designed for use in sulfuric acid related industries, Alloy 20 is now a popular choice for a wide variety of industries including the chemical, food, pharmaceutical, and plastics industries. In addition, this superalloy is used in heat exchangers, mixing tanks, metal cleaning and pickling equipment, and piping.

ASME SB 729 N08020 Alloy 20 Pipe Chemical Composition

| Alloy | % | C | Mn | P | S | Si | Ni | Cr | Mo | Cu | Nb+Ta | Fe |

| ASME SB 729 N08020 | min. | – | – | – | – | – | 32.00 | 19.00 | 2.00 | 3.00 | 8×C | Rest |

| ASME SB 729 N08020 | max. | 0.07 | 2.00 | 0.045 | 0.035 | 1.00 | 38.00 | 21.00 | 3.00 | 4.00 | 1.00 |

DIN 17744 2.4660 Alloy 20 Tube Chemical Composition

| Alloy | % | Ni | C | Co | Cr | Cu | Fe | Mn | Mo | Nb+Ta | P | S | Si |

| DIN 17751 2.4660 | min. | 32.0 | – | – | 19.0 | 3.0 | Rest | – | 2.0 | 8×C | – | – | – |

| DIN 17751 2.4660 | max. | 38.0 | 0.07 | 1.5 | 21.0 | 4.0 | – | 2.0 | 3.0 | 1.00 | 0.025 | 0.015 | 1.00 |

ASME SB 729 N08020 Alloy 20 Pipe Mechanical Properties

| Alloy | Tensile strength Rm N/mm² ksi (MPa) min | Yield strength Rp0. 2N/mm² ksi (MPa) min | Elongation in 2in. (50.8mm) or 4D min, % |

| ASME SB 729 N08020 | 80 (550) | 35 (240) | 30.0 |

DIN 17751 2.4660 Alloy 20 Pipe Mechanical Properties

| Material Grade | Tensile Strength Rm N/mm²(MPa) min | Yield Strength Rp0.2% N/mm²(MPa) min | Yield Strength Rp 1.0% N/mm²(MPa) min | Elongation (%) | Brinell Hardness HBW 2.5/62.5 max | Brinell Hardness HBW 2.5/62.5 Approximately | |

| Alloy 20 2.4660 | Annealed | 550 | 240 | 270 | 40 | 220 | – |

| Material No. | DIN 17744 17750 17751 17752 17753 2.4660 |

| EN symbol (short) | NiCr20CuMo |

| AISI/SAE | — |

| UNS | ASTM A182 A240 B366 B463 B464 B468 B729 N08020 |

| AFNOR | — |

| B.S. | — |

| alloy | Alloy 20 |

| Registered work’s label | Nicrofer® 3620Nb Carpenter® 20 and Incoloy® 20 |

Pipe and Tube

ASTM B 464 N08020 Alloy 20 Pipe

ASME SB 729 N08020 Alloy 20 Tubing

ASME SB 468 N08020 Alloy 20 Tubes

ISO 6207

DIN 17744 17750 17751 17752 17753 2.4660